Whether you need parts for your tractor or traffic products Ontario, medical equipment, or handyman tools, you’ll likely find yourself working with die cast metal at some point. If you’ve ever wondered about the process or what makes die cast metal different from anything else, you’ve come to the right place to learn.

What Makes Die Casting Different?

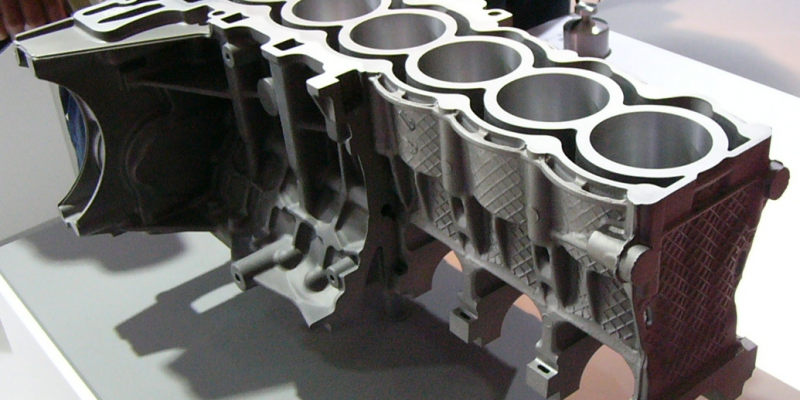

If manufacturers use a die casting process, it means that they’ve forced molten metal into a mold to form the final shape they want. The other type of molds they could use is made of sand, leading to the appropriate title of sand casting.

Die casting molds are usually composed of non-ferrous metals like aluminum, zinc, lead, or others. The main benefit of die casting is that the company will have a permanent mold, rather than a sand one that can only make one part. That metal form enables them to make as many pieces with the same dimensions as necessary to complete the job.

What is the Die Casting Process?

The die casting process starts with melting metal, like steel, down into a liquid. Only metals with a lower melting point than that of the mold should undergo this process, or else the mold will melt with it. The molten metal will flow into the pouring basin, which in turn encourages it into the casting cavity.

The processor will use high pressure or allow gravity to work for them to force the liquid into the mold cavity, which is surrounded by the two parts of the die. If using artificial pressure, the machine will have a plunger attached to apply the right amount of pressure to the metal.

As the molten metal cools down, it will harden and take the form of its cast. The metalworker will take off the top of the die and use ejecting pins to remove the new part from its mold.

Comments