Chemical etching of stainless steel is a process of removing metal using a chemical process. It provides many benefits. Since no heat or force is used in the process, it doesn’t stress the metal like other processes. It also allows for the manufacturing of very intricate or complex parts.

How Does Chemical Etching of Stainless Steel Work?

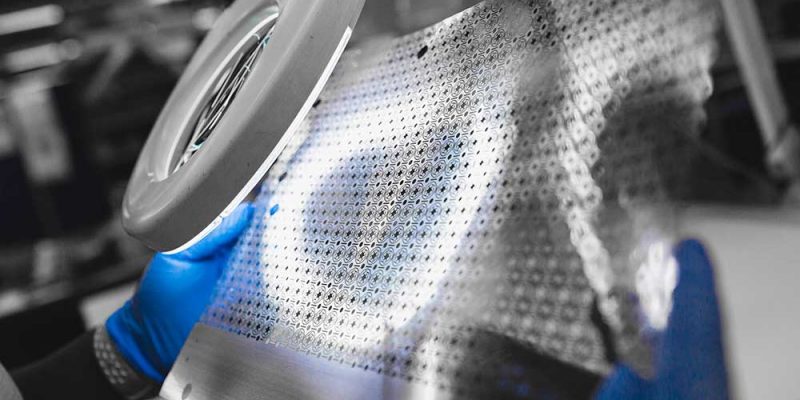

The stainless steel is laminated with a light-sensitive photoresist which is then exposed to UV light. This transfers a CAD image to the part. The unexposed areas are then developed and sprayed with a chemical etchant to precisely remove the desired areas. The part is then stripped of the remaining photoresist.

The process uses digital tooling. This eliminates the need for expensive molds. Consistency is maintained because there is no tooling to wear over time. There is no difference from the first part to the last part which is often observed using other methods. Chemical etching of stainless steel is suitable for prototypes and large production runs because the tooling can be easily changed.

When compared to stamped parts, chemical etching provides a 90% faster turnaround time. It also avoids the significant investment in tooling required for stamped or molded parts. Chemical etching is also seen as more accessible than other methods. Its quick turn around time and relatively low initial investment allow for greater innovation.

Products Manufactured with Chemical Etching of Stainless Steel

Chemical etching of stainless steel can be used to produce meshes and filters. It produces no burrs and creates no stress on the material. It also allows for precision removal of different areas quickly and economically.

It’s also beneficial when a highly aesthetic finish is desired. It can be used to produce a wide array of intricate products, including grilles for automotive speakers. Intricate designs can be difficult to produce with stamping, and laser cutting may not provide ideal tolerances.

Fuel cell plates and cooling plates can also be produced with chemical etching of stainless steel. Grooves are often needed on both sides of the plates. Chemical etching allows both sides to be processed at the same time, making it more economical and accurate than other methods. CNC machining can be used to manufacture fuel cell plates. However, it can be difficult to achieve the proper flatness and remove burrs using CNC machining.

Comments